Send Inquiry, Get Accurate Quotation

6 Axle Mega Windmill Transporter Mounted on 3 Line 6 Axle Lowbed can lift the wind turbine blades, it usually transport the wind turbine blades to the top of the mountain.

In the wind power industry, Shiyun vehicle mainly have wind power nacelle, wind turbine blades, wind tower section, etc. to complete industrial chain. Shiyun vehicle provide all types transportation solutions for the wide power industry use.

Comparing with extendable wind blade trailer ,The 6 axle mega windmill transporter with lowbed can raise, swing, and rotate the blades. It can avoid various obstacles such as trees, mountains, and wires on the way, effectively solve the problem of wind blade transportation in mountain areas, and directly grasp the wind blades by the hydraulic power station. In the case of high wind, the blades can rotate 360 degrees to avoid the wind, and participate in the balance through the counterweight to ensure transportation safety.

6 Axle Mega Windmill Transporter for Sale - Shiyun Vehicle

6 Axle Mega Windmill Transporter for Sale - Shiyun Vehicle

Brand: Shiyun 6 Axle Mega Windmill Transporter

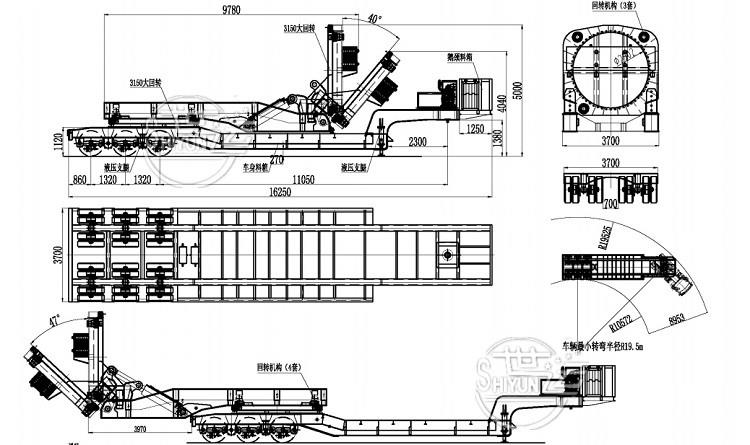

Dimension: 16250mm*3700mm*5000mm

Applicable blade: 80m, 121-156 model windmill blades

Loading capacity: 23.5 Tons

Axle: 3 lines 6 axles

Tires: 24 units

Max rotation angle: 360°

Lifting cylinder: cylinder diameter 280mm Lift angle 0-55

Gooseneck with an active platform: 1m

Hydraulic station: 31KW four-cylinder diesel engine

Landing gear: Front and rear hydraulic support cylinder

King pin: 2.00 or 3.5 inch bolt-in king pin

Lubrication and maintenance (tooling lubrication points)

The engine oil tank must be checked for the amount of oil daily, and the oil should be added in time to prevent the lack of oil from causing damage to the machine, and the hydraulic system has no oil leakage during work.

The upper and lower slewing ring raceways should be filled with grease regularly. When filling the grease, the slewing ring should be slowly rotated to make the grease filled evenly.

Pay attention to the operation of the slewing bearing in daily use. If you find abnormal noise, impact, or sudden increase in power, you should stop the machine immediately for inspection and troubleshoot.

Adjust the system pressure by adjusting the overflow valve on the hydraulic oil tank (the initial pressure is 16-18Mpa when lifting). The large and small gears of the slewing ring and the slewing mechanism must be greased to maintain lubrication and reduce dry wear.

The connecting bolts of the blade flange and the tooling mounting plate must be tightened.

The speed of the vehicle should be controlled within 20km/hour in complex road conditions.